Acrylic Coated Welding Blanket Manufacturer | OEM Heat Shield Mat from China

Factory-direct welding fire blankets made of fiberglass and silicone coatings. Up to 1000°C heat resistance. Custom sizes, OEM branding, global shipping.

keywords:

Category:

Welding Blankets

Welding Fire Blanket for Industrial Safety Applications

As a professional fire blanket manufacturer serving industrial users such as welders, engineers, and metal fabricators, we supply durable welding fire blankets engineered for extreme heat resistance and workplace fire safety. Whether you're shielding equipment or creating a spark-free zone for hot work, our fiberglass welding fire blankets offer performance, compliance, and customization trusted by global OEM clients.

High-Temperature Resistant Welding Fire Blankets for Sparks, Slag, and Splatter Control

Welding blankets—also referred to as welding mats or welding drapes—are critical for preventing fire incidents and heat damage during high-risk operations like cutting, grinding, or welding. Our industrial-grade blankets are constructed from flame-retardant fiberglass or silicone-coated fiberglass, capable of withstanding temperatures up to 1000°C.

Designed to shield both personnel and nearby equipment, these fire-retardant covers reduce workplace hazards, ensuring safety compliance and minimizing fire-related downtime. Whether laid flat or draped vertically, they form a thermal barrier against molten metal and hot debris.

In-Depth Overview of Acrylic-Coated Welding Fire Blankets from a Certified Chinese Manufacturer

ITEM | STANDARD |

Made in | China |

Material | Fiberglass Cloth + Acrylic Coating |

g/㎡ | 500gsm-1900gsm |

Thickness | 0.6mm-2mm |

Services | OEM/ODM/Customization/Free sample |

Color | Black/red/yellow or Customized |

Size | 1.8m*1.8m,2m*2m, 2m*3m, or Customized |

Continuous Heat | 550℃ |

Surface | Acrylic Coated |

MOQ | 100 pieces |

Technical Overview of High-Temperature Acrylic-Coated Welding Fabrics

Performance Benefits of Fire-Retardant Acrylic-Coated Welding Protection Fabrics

Acrylic-coated welding safety sheets, often referred to as thermal shielding mats or heat-resistant fireproof fabrics, are engineered to withstand extreme temperatures while offering long-term protection in industrial environments. These welding covers are ideal for shielding personnel, equipment, and flammable surfaces during hot work operations such as welding, grinding, or cutting.

• Material Composition:

Constructed from industrial-grade fiberglass, silica fabric, or coated fire-retardant textile with excellent tensile strength and thermal insulation.

• Temperature Withstanding Capacity:

Supports continuous exposure up to 1000°C, suitable for heavy-duty welding applications and flame-intensive environments.

• Surface Coating Options:

Choose from durable coatings such as acrylic, silicone, vermiculite, or aluminum foil for enhanced resistance against heat, sparks, and corrosive elements.

• Global Safety Certifications:

Meets stringent standards including EN ISO 11611 for welding protection, EN 13501-1 for flame performance, and CE compliance.

• Flexible Sizing Solutions:

Available in standard and custom dimensions from 1x1m to 4x8m, with tailored configurations for OEM and project-based bulk orders.

• Versatile Application Fields:

Commonly used in manufacturing plants, shipyards, and workshops as fire barriers, welding drapes, heat shields, or equipment insulation wraps.

• Designed for Demanding Conditions:

Engineered to perform in high-temperature zones, with minimal degradation and stable structural integrity under thermal stress.

• Acrylic Surface Protection:

Water-resistant and chemically resilient surface effectively repels oil, grease, acids, and industrial solvents.

• Enhanced Handling Safety:

Smooth finish minimizes fiber irritation, offering improved flexibility and easier deployment during frequent use.

• Multi-Layer Heat Defense System:

Features a reinforced fiberglass core, high-performance acrylic coating, and embedded flame-retardant agents for superior thermal protection.

• Fully Customizable Options:

Adjustable thickness (1–5mm), personalized sizing, edge finishing (grommets, Velcro, straps), and private-label branding support.

Core Industrial Applications of Acrylic-Coated Fireproof Welding Covers

Acrylic-coated fireproof welding covers—commonly known as industrial thermal shielding blankets or flame-retardant welding mats—are engineered for high-risk operational zones requiring reliable protection from heat, sparks, and slag. These fiberglass-based fire barriers serve a vital role across multiple heavy-duty sectors where precision, durability, and fire safety compliance are essential.

• Automotive Welding Facilities: Acts as a thermal safety shield draped over sensitive components like fuel lines, batteries, and engine assemblies during hot work maintenance.

• Shipbuilding and Offshore Decks: Prevents molten slag or welding sparks from damaging structural platforms, cables, and combustible marine equipment.

• Petrochemical and Gas Refineries: Functions as a heat-resistant insulation mat when welding pipelines near volatile vapors or pressurized tanks.

• Structural Steel Fabrication: Used as a flame-blocking drape to isolate flammable construction materials, scaffolding joints, and temporary frameworks.

• Battery & Electronics Production Lines: Deployed beneath lithium assembly units to prevent floor ignition risks and protect delicate electronic enclosures.

• Aerospace and Railway Workshops: Essential for shielding avionics and precision metal parts during arc welding or plasma cutting operations.

• Maintenance in Hazardous Environments: Provides a flexible fire barrier solution for confined spaces, engine rooms, or utility vaults with combustible residues.

OEM Acrylic-Coated Welding Blankets | China Factory Direct Supply

We manufacture OEM acrylic-coated fiberglass welding blankets tailored for industrial clients and bulk distributors. This coating improves flexibility and wear resistance, while maintaining superior heat insulation. Delivered directly from our China factory, our products combine high performance with price competitiveness.

Advantages of Acrylic Coated Fiberglass Welding Blankets

• Enhanced Flame Resistance: Acrylic treatment offers additional spark insulation

• Improved Flexibility: Easier to roll, fold, and position around complex shapes

• Chemical Resistance: Suitable for environments exposed to oils and greases

• Longer Service Life: Reduced fraying and better abrasion resistance

Solving Common Industrial Pain Points with Welding Blankets

1. Fire Hazard Mitigation During Hot Work

During welding, sparks and molten particles can easily ignite flammable materials. Our blankets form a fireproof barrier using treated fiberglass, helping industrial users meet fire code compliance and prevent costly incidents.

2. Thermal Insulation for Sensitive Surfaces

Capable of withstanding up to 1450–1650°C on the surface, our welding drapes protect precision equipment, electronics, or combustible substrates from radiant heat and thermal shock.

3. Operational Efficiency and Flexibility

Traditional metal shields are heavy and inflexible. Our lightweight welding blankets are reinforced with aluminum or acrylic coatings for better maneuverability—allowing workers to deploy and reposition them quickly on-site.

4. Maintenance Risk Reduction and Cost Savings

Neglecting to replace damaged welding blankets can result in catastrophic losses. We help clients implement blanket inspection routines and offer replacements at factory-direct prices—lowering downtime and repair costs.

Request Free Samples or Bulk Pricing for Welding Blankets Today

We support global B2B clients with free samples, low MOQs, fast production turnaround, and DDP shipping to the US, EU, and Middle East. Whether you’re sourcing for resale, industrial application, or OEM projects, our team delivers trusted protection where heat meets risk.

What Sets Kun'An OEM Heat-Resistant Fiberglass Welding Covers Apart

Kun'An acrylic-coated fiberglass welding blankets, engineered for high-heat industrial safety applications, deliver a blend of durability, flexibility, and cost control ideal for OEM clients and global distributors. These customizable flame-retardant covers are trusted in shipyards, power plants, and metal fabrication zones for their consistent performance under extreme thermal stress.

• OEM-Level Customization for Fireproof Welding Mats

From custom coatings (acrylic, silicone, vermiculite) to color-coded fabrics and tailored sizing, we support MOQ as low as 50 units—ideal for branded distribution or niche industrial use.

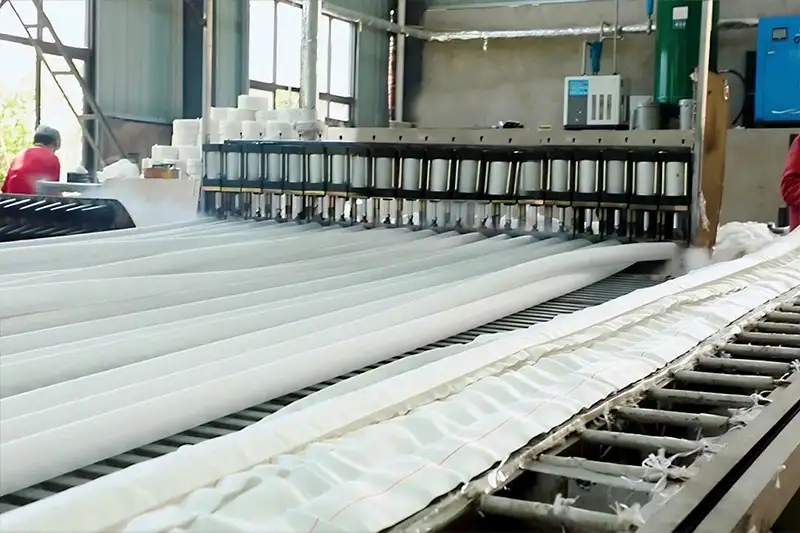

• Efficient Production for Large-Scale Welding Protection Orders

With in-house fabrication and inventory control, most bulk shipments are completed within 15–20 business days, helping integrators and wholesalers meet tight project schedules.

• Factory-Direct Pricing for Industrial Thermal Shields

Eliminate middlemen with competitive factory pricing—achieving up to 40% cost reduction compared to third-party brands, without compromising EN or CE compliance.

• Durable Flame Shielding for High-Risk Environments

Each blanket is designed for continuous exposure up to 1000°C, ensuring reliable thermal defense during MIG, TIG, or arc welding, as well as for cutting and grinding operations.

• Reliable Partner for Global Welding Safety Supply Chains

As a specialized fire blanket manufacturer in China, we serve clients across construction, aerospace, energy, and manufacturing industries—offering export-ready documentation and quality consistency.

CONTACT US

Previous page

QUALITY CONTROL

BROWSE OUR FIRE SUPPRESSION SOLUTIONS

Interested In Our Product

Enter your contact information and we will contact you as soon as possible

FACTORY WORKSHOP

Related Products

Special Hazards Suppression Systems | Clean Agent Fire Protection

Restaurant Hood Suppression Systems | Reliable Commercial Kitchen Fire Safety

Fire Sprinkler System for Comprehensive Fire Protection