Industrial Welding Blanket Applications | Heat-Resistant Covers Supplier

Discover heat-resistant welding blankets for heavy industry, from arc flash protection to cleanroom retrofits. OEM factory direct with global delivery.

keywords:

Category:

Welding Blankets

China-Manufactured Heat-Resistant Welding Blankets | Wholesale Fiberglass and Silica Cloth Solutions

Engineered for high-temperature industrial protection, our China-manufactured thermal insulation blankets are built from premium fiberglass and high-silica textiles, offering reliable performance for welding, grinding, and cutting operations. These flame-retardant welding sheets are ideal for applications requiring consistent heat shielding in shipbuilding, oil & gas facilities, and structural steel fabrication. We support bulk OEM orders, flexible sizes, and global delivery—tailored to your operational safety needs.

Comprehensive Overview of Industrial Heat-Resistant Welding Blankets | OEM Fiberglass & Silica Cloth Supplier from China

ITEM | STANDARD |

Made in | China |

Material | 100% fiberglass/high silica fabirc/ coated fiberglass&high silica fabirc |

g/㎡ | 840gsm~1100gsm or other |

Thickness | 0.85mm-1.3mm or ohter |

Services | OEM/ODM/Customization/Free sample |

Color | Golden Yellow/White,or Customization |

Roll Lenth | 50m or Customization |

Working Temperature Resistance | 800°C-1600°C |

Width | Customization |

Enhanced Fire-Retardant Welding Blanket Specifications for High-Heat Industrial Safety

1. Engineered Fabric Choices for Extreme-Temperature Welding Zones

Our heat-insulated welding blankets are manufactured from premium-grade fiberglass and high-silica cloths, each engineered to withstand different thermal exposure levels.

• Fiberglass welding fabric offers stable protection up to 1000°C, ideal for mechanical shops, light-duty metalwork, and auto-body repair.

• High-silica thermal shields, tested for continuous resistance to 1600°C, deliver unmatched safety for foundries, shipbuilding yards, and petrochemical sites where molten splatter and radiant heat are frequent.

This material variety solves the critical pain point of material mismatch in high-risk welding environments, ensuring correct thermal coverage without over-specification cost.

2. Multi-Layered Heat Defense with Industrial Coating Systems

Each blanket is treated with silicone, acrylic, or vermiculite-based coatings, depending on required use case. These specialized finishes enhance protection against:

• Sparks, slag ejection, and welding arc radiation

• Molten metal drips and grinding flash

• Exposure to open flame or intense heat zones

The coatings are non-combustible, flame-retardant, and help maintain dimensional stability under stress. This multi-layer system directly addresses concerns over blanket degradation, which often compromises worker safety and requires frequent replacement in heavy-duty workflows.

3. Flexible Manufacturing and Custom Configurations for OEM Orders

We offer full customization across blanket thickness, width, grommet spacing, and folding pattern. Available enhancements include:

• Fireproof Kevlar thread stitching

• Reinforced hems with brass eyelets

• Branding options for OEM or private label

Real-World Applications Where Welding Blankets Solve Critical Safety Gaps

• Refinery Hot Work Zones: Stop Vapor Ignition Before It Starts

Flammable gas pockets and high-temp welding don't mix. In petroleum and gas refineries, our slag-resistant welding barriers provide essential spark isolation around pressure vessels and manifolds. The right thermal shield prevents flashover and reduces shutdown risk.

• Shipbuilding Interiors: Limit Fire Spread in Confined Hull Spaces

Steel cutting in ship compartments often happens near paint, fuel lines, or insulation. Our marine-approved fireproof cloths contain slag, reduce ambient heat exposure, and stay stable in humid coastal environments — critical for engine rooms and deck welding.

• Steel Frame Construction: Protect Lower Floors from Falling Sparks

On multi-floor job sites, welding at height creates a vertical hazard chain. Drop-resistant heat blankets prevent slag from igniting lower-level materials like insulation or wood decking. Lightweight and reinforced, they’re easy for crews to reposition between zones.

• Electrical Room Maintenance: Shield Live Equipment During Hot Work

Welding near panels or control boxes? Use non-conductive fire blankets to isolate heat without adding arc flash risk. These are essential during retrofits or emergency fixes in utility tunnels and plant substations.

• Foundry Pouring & Forging: Control Radiant Heat and Metal Splash

Molten metal splash can travel meters from the pour point. High-silica thermal fabrics withstand direct radiant loads and splash from ladles or induction furnaces, giving crews a reliable perimeter barrier around high-risk workstations.

CONTACT US

QUALITY CONTROL

BROWSE OUR FIRE SUPPRESSION SOLUTIONS

Interested In Our Product

Enter your contact information and we will contact you as soon as possible

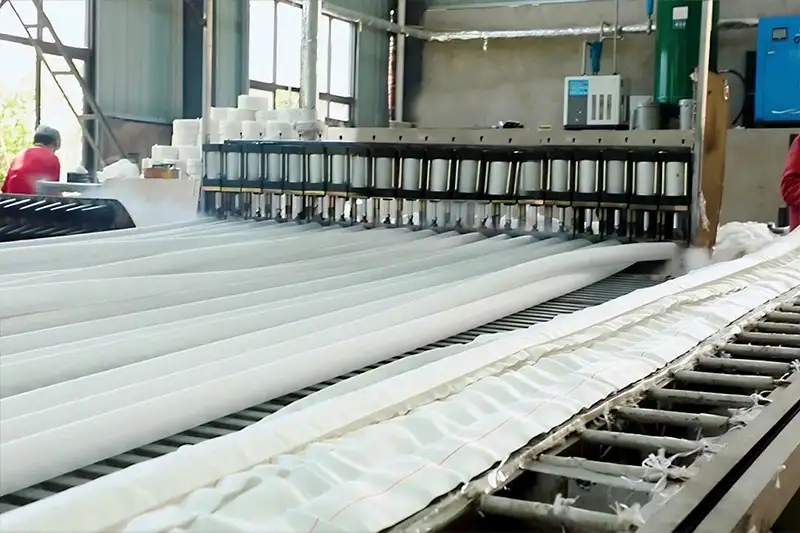

FACTORY WORKSHOP

Related Products

Special Hazards Suppression Systems | Clean Agent Fire Protection

Restaurant Hood Suppression Systems | Reliable Commercial Kitchen Fire Safety

Fire Sprinkler System for Comprehensive Fire Protection